In the competitive world of aluminum smelting, improving production efficiency is crucial for maintaining profitability and sustainability. Innovative materials are at the forefront of this transformation, playing a vital role in enhancing operational performance.

.jpg)

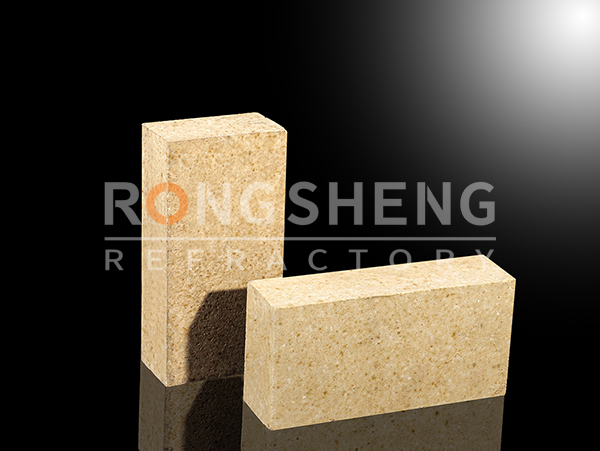

High alumina bricks are a key component in the refractories used in smelting operations. Their superior thermal stability and chemical resistance significantly contribute to the overall efficiency of the smelting process.

Advancements in refractory materials, including tailored high alumina shaped bricks, have led to significant improvements in erosion resistance and thermal efficiency. These innovations reduce downtime and lower operational costs.

Implementing innovative materials not only boosts productivity but also aligns with sustainable manufacturing goals. By reducing waste and energy consumption, modern smelting facilities can minimize their ecological footprint.

In conclusion, the adoption of innovative materials in aluminum smelting is a game-changer. By enhancing production efficiency and promoting sustainable practices, these materials are paving the way for a more competitive and environmentally responsible industry.